LPG Tanks (Tanks for Liquefied Petroleum Gas Storage)

LPG Distribution EquipmentAll Axiom supplied tanks are designed and manufactured in accordance with the latest edition and addenda of ASME Code for Pressure Vessels, Section VIII, Div. 1. Manufactured with steel meeting A.S.T.M. standards.

General specifications include:

- Design pressure at 17.2 bar (250 PSI)

- Design temperature 51.5°C (125°F)

- Hydrostatic test pressure at:

- 4 bar (325 PSI) min.

- 2 bar (395 PSI) max.

Tank Types

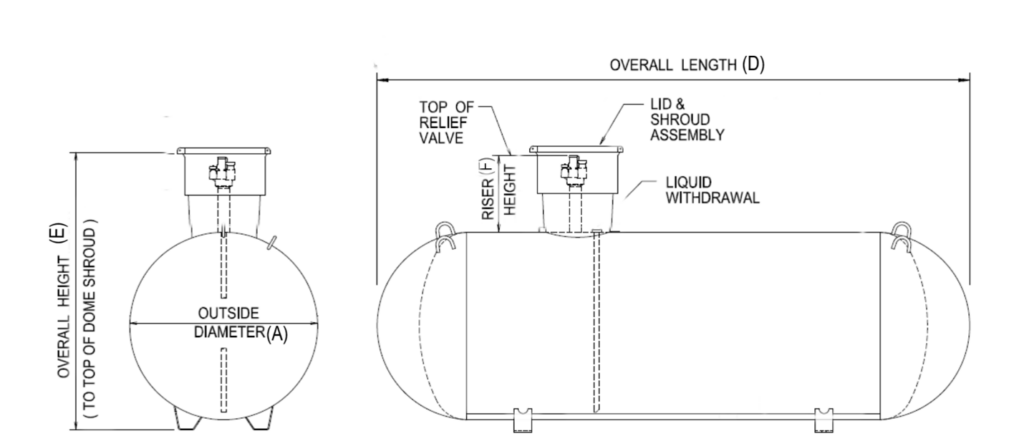

Tank Models:

| Model | Nominal Capacity | Empty Weight (KG) | Diameter (A) mm | Overall Length (D) mm | Overall Height (E) mm at Riser Height (F) of: | |||

|---|---|---|---|---|---|---|---|---|

| Gallons | Liters | Gallons | Liters | 14″ | 28″ | |||

| 500 | 1893 | 498 | 965 | 418 | 950 | 2990 | 1510 | 1770 |

| 1000 | 3785 | 996 | 3770 | 785 | 1040 | 4850 | 1600 | 1860 |

| 1250 | 4732 | 1241 | 4698 | 907 | 1040 | 5960 | 1570 | 1860 |

| 2000 | 7570 | 2013 | 7620 | 1671 | 1180 | 7240 | 1710 | 2060 |

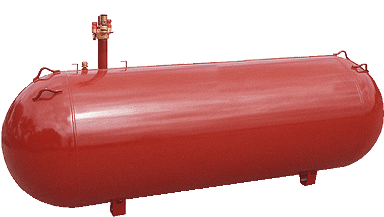

Features of Axiom supplied Horizontal Underground Tanks:

VERTICAL DOMESTIC UNDERGROUND TANKS:

| Model | Nominal Capacity | Empty Weight (KG) | Diameter (A) mm | Overall Height (B) mm | Design Pressure: | |||

|---|---|---|---|---|---|---|---|---|

| Gallons | Liters | Gallons | Liters | PSI | Bar | |||

| 650 | 2450 | 647 | 2450 | 602 | 1188 | 2692 | 250 | 17.2 |

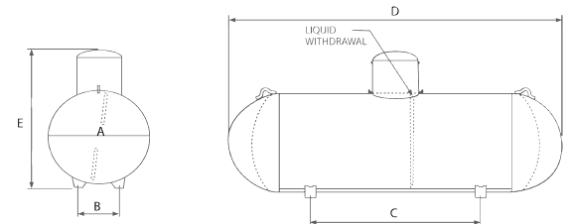

ABOVE-GROUND HORIZONTAL TANKS:

| Model | Nominal Capacity | Empty Weight (KG) | Diameter (A) mm | Width Between Leg Supports (B) mm | Length Between Leg Supprts (B) mm | Overall Length (D) mm | Overall Height (E) mm | ||

|---|---|---|---|---|---|---|---|---|---|

| Gallons | Liters | Gallons | Liters | ||||||

| 500 | 1893 | 498 | 965 | 395 | 950 | 380 | 1520 | 2990 | 1160 |

| 1000 | 3785 | 996 | 3770 | 784 | 1040 | 410 | 2740 | 4850 | 1250 |

| 1250 | 4732 | 1241 | 4698 | 907 | 1040 | 410 | 3890 | 5900 | 1250 |

| 2000W | 7570W | 2013 | 7620 | 1668 | 1180 | 533 | 6096 | 7240 | 1710 |

| 2000L | 7570L | 1978 | 7488 | 1421 | 1040 | 483 | 4940 | 9320 | 1270 |

Features of Axiom supplied Horizontal Above-Ground Tanks:

| # | Details |

|---|---|

| 1- | ASME “U” Stamped tanks |

| 2- | Brass valves and accessories include:

|

| 3- | Super durable two-layer powder coating with zinc rich primer and TGIC polyester final coat |

| 4- | Tanks are vacuum pre-purged to save time, money and product |

| 5- | Dual lifting lugs for easier installation |

| 6- | Axiom stocks all parts and accessories of the tanks that may be needed for proper installation and maintenance |

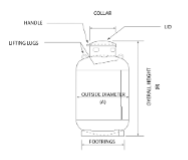

VERTICAL DOMESTIC ABOVE-GROUND TANKS:

| Model | Nominal Capacity | Empty Weight (KG) | Diameter (A) mm | Overall Height (B) mm | Design Pressure: | |||

|---|---|---|---|---|---|---|---|---|

| Gallons | Liters | Gallons | Liters | PSI | Bar | |||

| 120 | 454 | 120 | 454 | 151 | 762 | 1280 | 250 | 17.2 |

Features of Axiom Supplied Vertical Above-Ground Tanks:

Other tank types and sizes available on special design/order basis.

Tank parts and accessories

To support or tanks, we have an extensive stock of tank parts and accessories

| # | Details |

|---|---|

| 1- | Multivalves |

| 2- | Service valves |

| 3- | Filler valves |

| 4- | Liquid withdrawal valves |

| 5- | Pressure Relief Valves |

| 6- | Float Gauges, float gauge dials and rubber seals |

| 7- | POL tank connections (pigtails) |

| 8- | Liquid service valves |

| 9- | Pressure Gauges |

| 10- | Valve bonnet replacement set |

| 11- | Multivalve wrenches |